Name:VAE RDP Redispersible polymer powder

YIDA® VAE/RDP is widely used in:

Cement

Lime

Gypsum-based

Dry-mix mortar

Tile adhesive

EIFS

Self-leveling

Grouting

AAC Block

| Chemical Name | Ethylene-vinyl acetate powder (VAE-RDP) |

| Exterior | White free flowing powder |

| Protective colloid | PVA |

| Solid content,% | 97-99 |

| Ash content,% | 10±2 13±2 15±2 |

| Bulk density, g/l | 300-500 |

| Particle size, μm | ≥80 |

| Model | YD1030 YD1060 YD1090 |

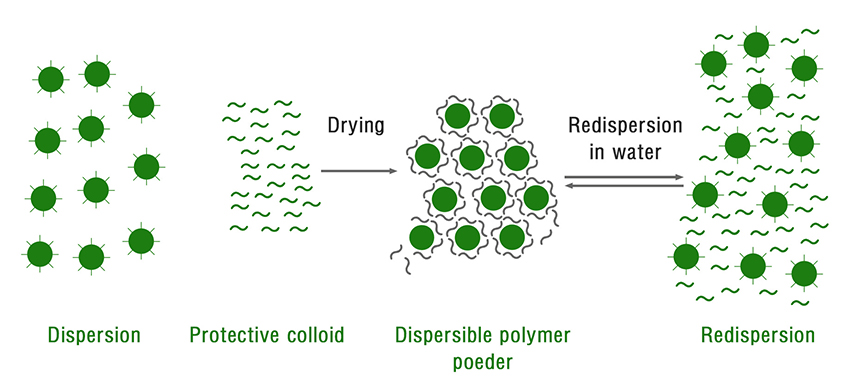

Ethylene-vinyl acetate rubber powder (VAE-RDP) is made of vinyl acetate/ethylene copolymer emulsion (EVA emulsion) modified by adding water-soluble protective colloid (polyvinyl alcohol usually PVA) and spray-dried, using water as the medium Can be re-formed into an emulsion, a powder with redispersibility.

(1) Redispersible polymer powder is easily soluble in water and easy to form emulsion.

(2) Redispersible polymer powder has strong cohesive force and good tensile force.

(3) Redispersible polymer powder can improve the processability, flexibility and impermeability of materials.

(4) Redispersible polymer powder can improve the cohesion of the mortar, increase the concentration and anti-sagging.

(5) Redispersible polymer powder can improve the flexibility of the mortar and extend the open time.

It can be packed in paper-plastic composite bag lined with polyethylene plastic bag, cardboard drum or plastic coated, etc. The net weight of each piece is 25KG. During storage and transportation, it should be protected from sun and rain, fire and moisture.

Hebei Yida Cellulose Co., Ltd. is a RDP manufacturer with 16 years of production experience.It has its own 16 RDP powder production lines with an annual output of 30,000 tons of RDP powder. Serving more than 500 customers in more than 40 countries.

Q1: What is the process of redispersing RDP Redispersible polymer Powder in water?

A: To redisperse RDP VAE, the powder is gradually added to clean, agitated water while maintaining a moderate stirring speed to avoid lump formation. The dispersion process may require temperature control and a specific pH adjustment to optimize redispersion efficiency.

Q2: What are the common challenges encountered during the handling and storage of RDP Redispersible polymer Powder?

A: Moisture absorption and agglomeration can be issues if RDP VAE is not properly stored in a cool, dry environment. Additionally, dust generation during handling requires adequate ventilation and personal protective equipment to minimize health risks.

Q3: How does the particle size of RDP Redispersible polymer Powder affect its performance?

A: Smaller particle sizes typically result in faster redispersion rates and more uniform emulsions, which can lead to improved film formation and enhanced material properties. However, smaller particles may also increase the surface area, potentially affecting storage stability.

Q4: What is the shelf life of RDP Redispersible polymer Powder, and how can it be extended?

A: Shelf life depends on storage conditions but is generally several months to a year. Proper storage in a cool, dry place with low humidity can significantly extend shelf life. Packaging that minimizes moisture and oxygen exposure is also crucial.

Q5: Can RDP Redispersible polymer Powder be used in combination with other additives to enhance specific properties?

A: Yes, RDP VAE can be formulated with various additives such as fibers, pigments, polymers, and chemical admixtures to tailor the final material's properties. The compatibility of these additives with RDP VAE must be carefully evaluated to ensure optimal performance.

Shijiazhuang City, Hebei Province, China

0311-88100555

[email protected]